Heat Pump VRF

Heat Pump VRF

-

6 Ton to 30 Ton

VRF

Features

• 30 Ton Max Capacity

• Non-polar CAN Technology

• Modules Rotation Operating

• Anticorrosive Golden Fins

• Emergency Operation Function

• Compact Design

• Wider Application Location

• High Efficiency

• Energy-saving

• Intelligent Debugging

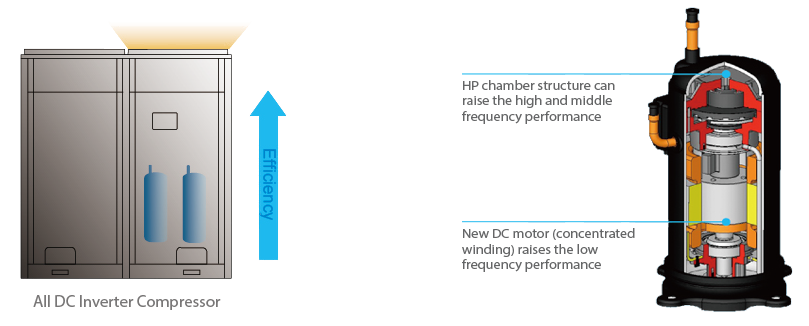

All DC inverter compressor and high-performance high pressure chamber are adopted to reduce loss of overheat and improve compression efficiency from direct intake. Compared with low pressure chamber, the compression efficiency is improved. High-efficient permasyn motor is adopted to provide better performance than traditional DC inverter compressor.

• All DC inverter compressor is used in this system. It can directly intake gas to reduce loss of overheat and improve efficiency.

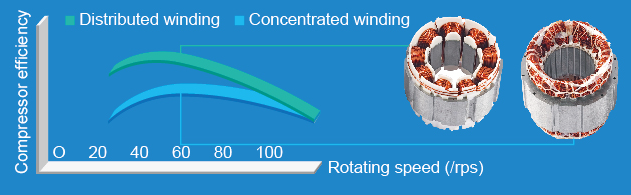

• High-efficient permasyn motor is adopted to improve better performance than traditional DC inverter compressor.

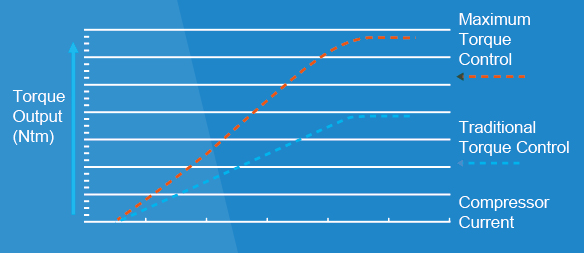

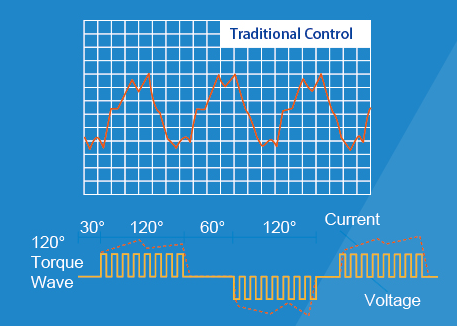

• Technology of Maximum Torque Control with Minimum Current

It can reduce energy loss caused by device winding so as to realize higher efficiency.

• Low-frequency Torque Control

It can directly control motor torque, through which fan motor can run at a low speed. Users will feel more comfortable while requirements of the system are also met.

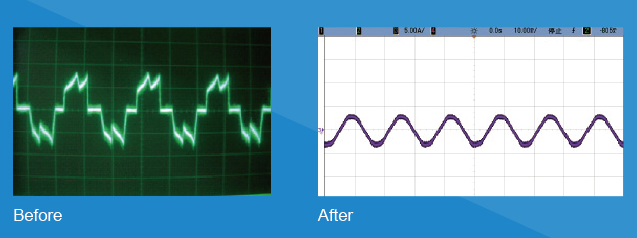

• 180° Since Wave DC Speed Varying Technology

It can satisfy various places and demands for different temperature and is able to save a great deal of electricity and provide users with utmost comfort at the same time.

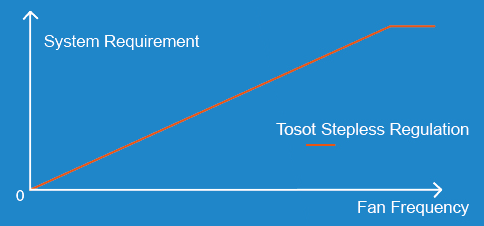

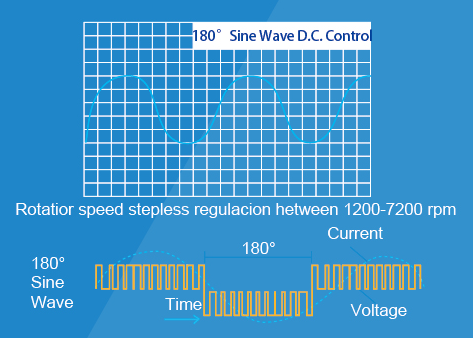

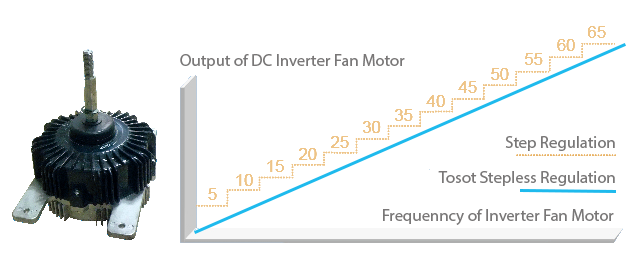

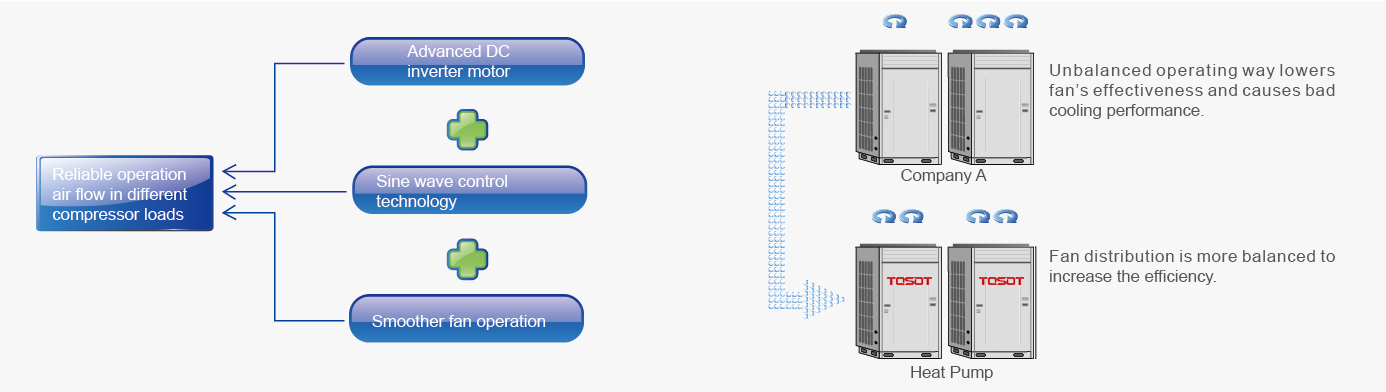

Sensorless DC Inverter Fan Motor

• Stepless speed regulation ranges from 5Hz to 44Hz. Compared with traditional inverter motors, the operation is more energy-saving.

• Sensorless control technology guarantees lower noise, less vibration and operation.

30 Ton Max Capacity – The Largest Free Combination

Max capacity of single outdoor unit reaches 10 Ton and max combination capacity is even up to 30 Ton, in an industry leading level.

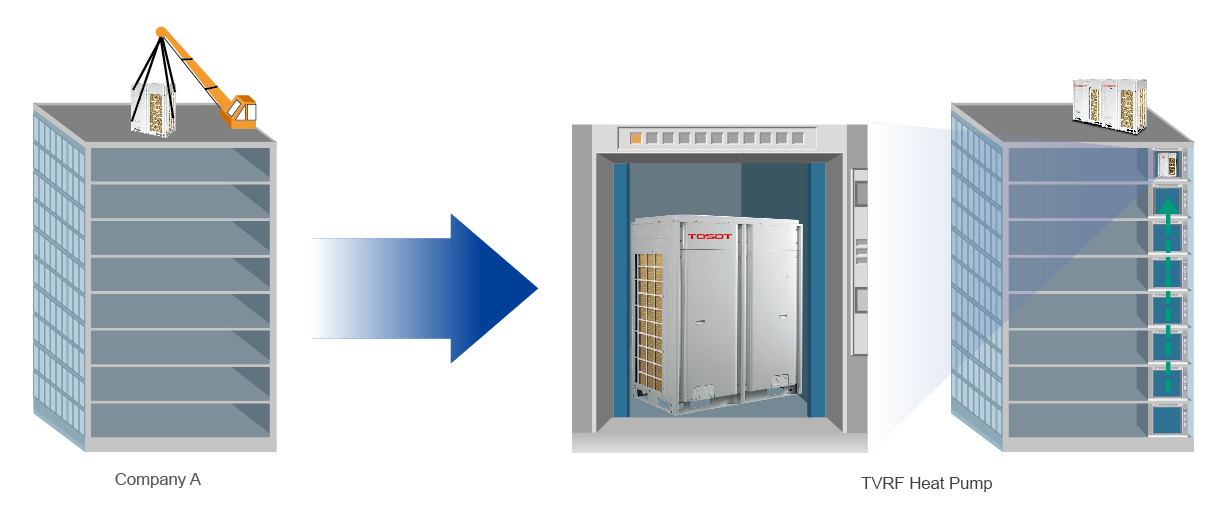

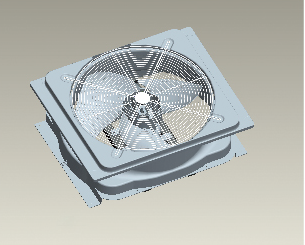

Compact Design

With compact design, the outdoor unit can be carried to the roof of building through elevator, with no need of crane. it is easier for delivery and installation.

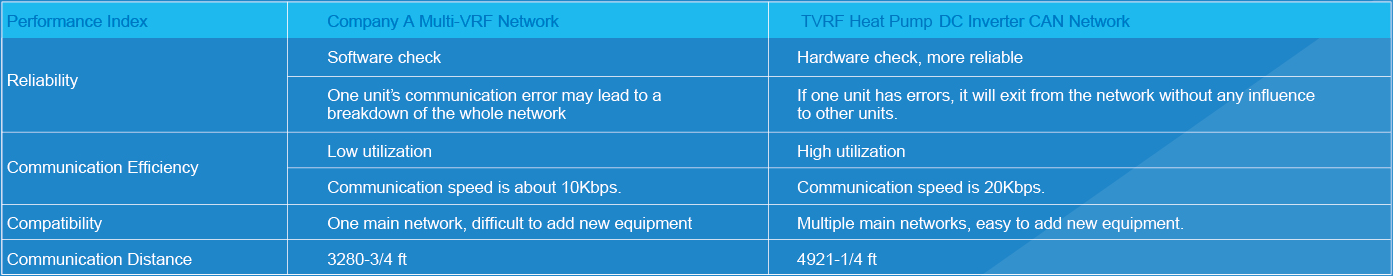

Non-polar CAN Technology to Improve Communication Efficiency

• Tosot is the first one to adopt non-polar CAN communication technology in the industry. CAN communication technology provides quicker system response speed, more convenient installation debugging and more reliable communication data.

• The non-polar CAN communication technology is applied to support flexible wiring installation, greatly reducing construction difficulties.

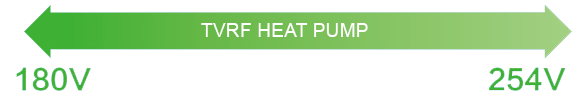

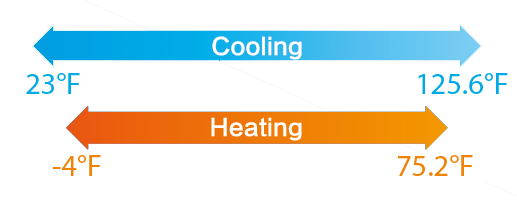

Wide Range of Voltage and Operation Condition

• Working voltage range of TVRF Heat Pump system has been improved to 180V~254V. For places with unsteady voltage, this system can still be running well.

• Outdoor operation temperature range is improved to 23°F~125.6°F in cooling and -4°F~75.2°F in heating.

Wider Application Location

TVRF Heat Pump can realize a combination of 3 outdoor unit modules connecting with as many as 61 indoor units. it’s especially applicable for business building or hotels

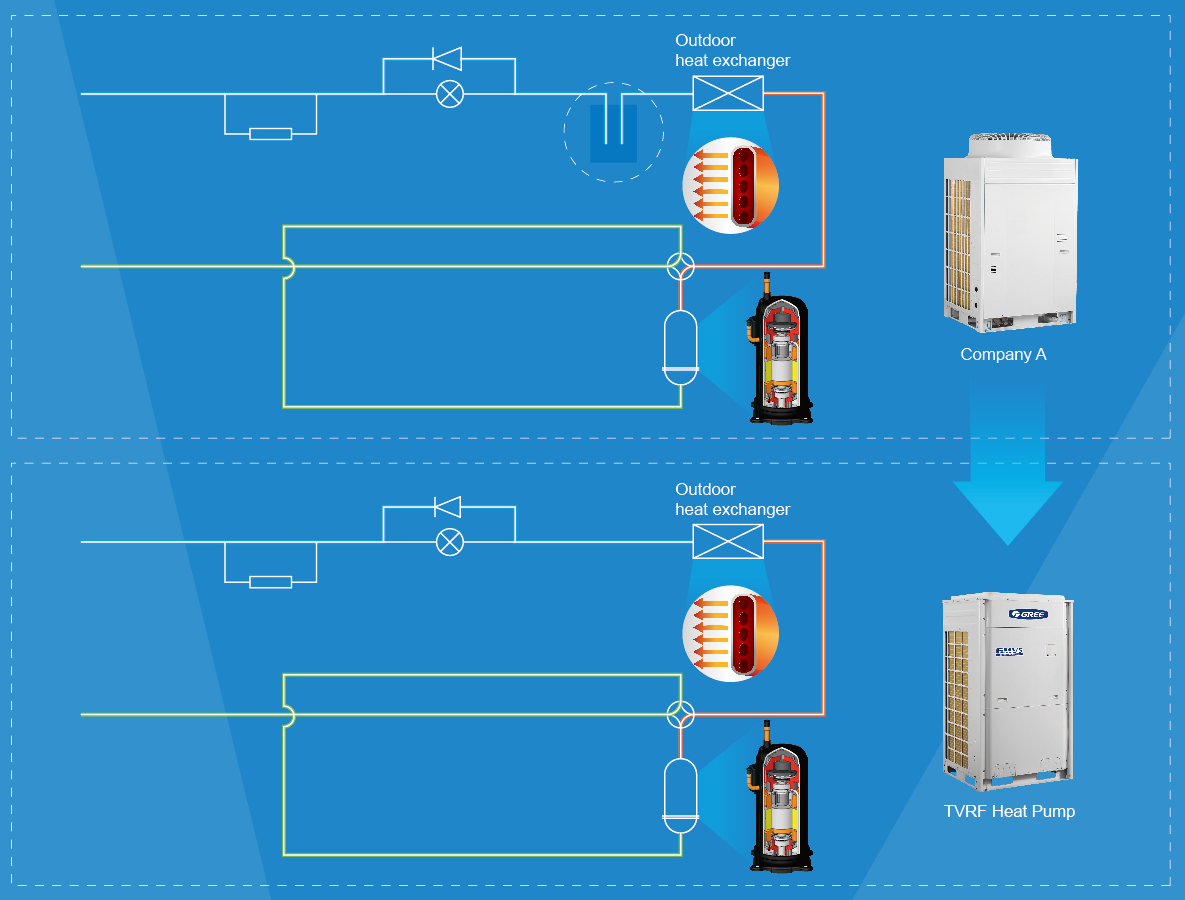

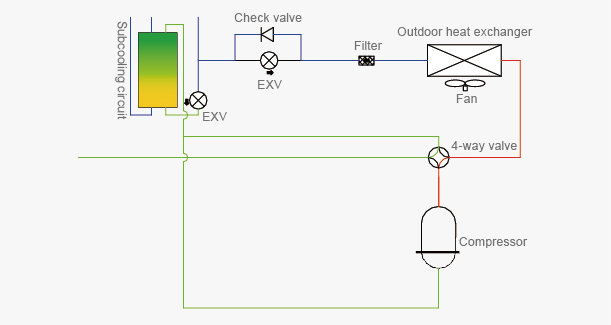

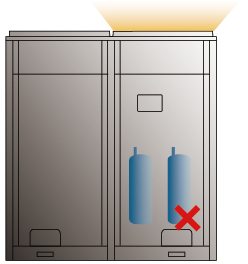

Refrigerant Storage and Distribution

The TVRF Heat Pump system is designed without liquid receiver and the excess refrigerant is stored in the piping, which can minimize the refrigerant charging volume and enhance the control accuracy of refrigerant.

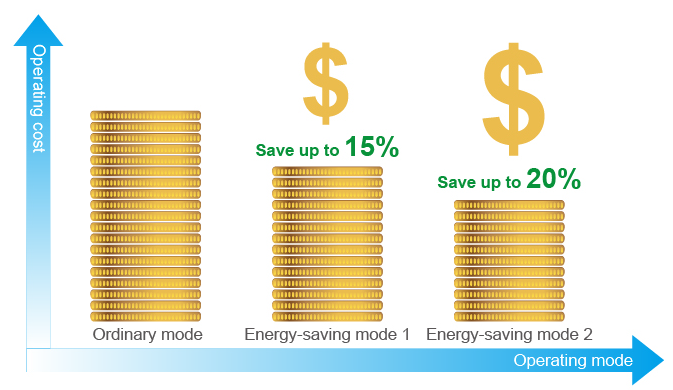

New Generation of Energy-saving Operation Control Technology with Energy Saving Up to 20%

The TVRF Heat Pump system has 2 modes for energy saving, which can be chosen to meet different electricity demands.

Mode 1

In auto energy-saving mode, the system will self-adjust parameters according to the operation status, thus to lower the cost of electricity. Up to 15% of energy can be saved.

Mode 2

In compulsory energy-saving mode, the system will limit power output forcibly. Up to %20 of energy can be saved.

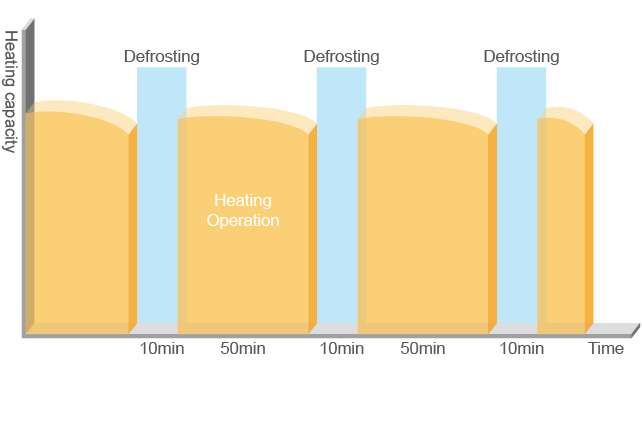

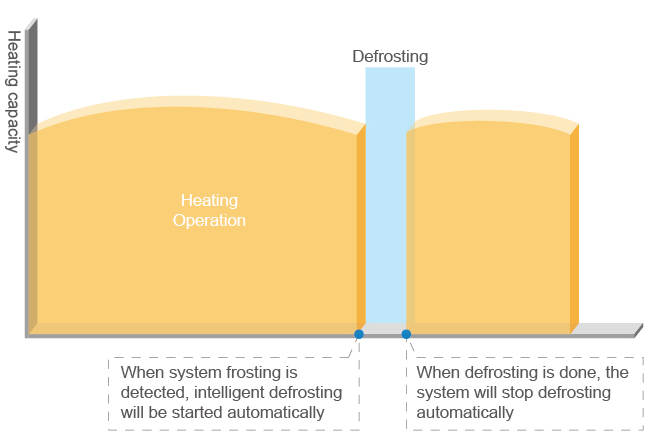

Comfortable Heating

Advanced intelligent defrosting mode is adopted. Tosot advanced intelligent defrosting mode will choose the best defrosting way according to outdoor temperature and operation status to realize intelligent defrosting, effectively improving heating effect and performance. While in traditional defrosting mode, timing defrosting is adopted, which not only affects comfort but also reduces energy efficiency.

Traditional Defrosting Mode

Tosot Intelligent Defrosting Mode

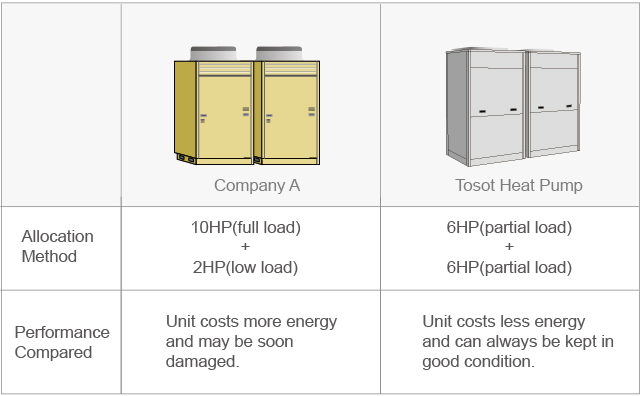

Accurate Intelligent Allocation Technology of Capacity and Output of Optimal Portion to Ensure Highest Efficiency

• When total load demands more than 75% of a running system’s capacity, one more unit will automatically start;

• When total load demands less than 40% of a running system’s capacity, one unit will automatically shut down;

• Therefore, each unit shares 40%-75% of the total load.

• Experiments show that an air conditioner costs the least energy when it’s operating within 40%-75% of its capacity.

• Output of Optimal Portion to Ensure Highest Efficiency

The best heating or cooling performance can be realized in the most energy-saving way. DC inverter compressor and DC inverter fan will also be operating in this way to ensure high efficiency.

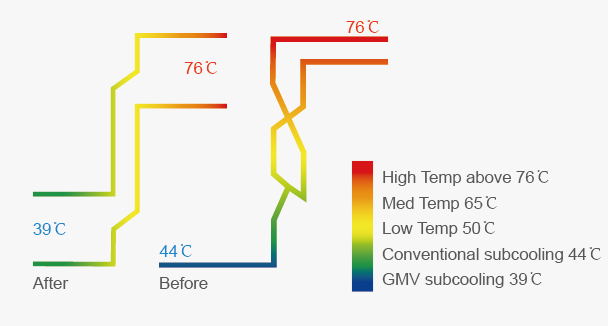

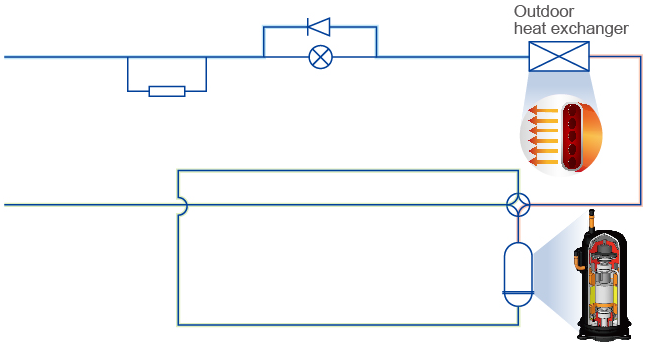

Sub-cooling Control Technology to Ensure Optimal Cooling and Heating

• Heat exchange loop can control the first subcooling process of heat exchanger. Subcooling degree can reach 11ºC.

• Subcooling loop can realize 9ºC second subcooling to guarantee cooling and heating performance.

Temperature Controlled by Wired Controller with Higher Efficiency and More Energy Saving

Through setting temperature lower limit in cooling or dry mode, and setting temperature upper limit in heating, 3D heating or heat supply mode, the system is able to operate in a smaller temperature range so as to achieve energy saving.

The TVRF Heat Pump system has a wide range of working conditions. Whether it’s in a cool winter or a hot summer, normal operation is guaranteed with the least noise, making users feel more comfortable.

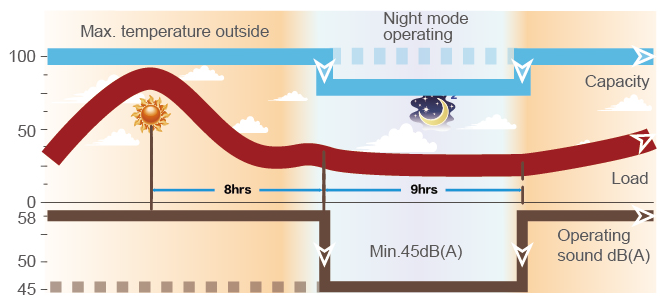

Outdoor Unit Quiet Mode and Quiet Control

• Quiet at night

The system can record the highest outdoor temperature. At night, the system will automatically turn to quiet mode. There are 9 quiet modes which can be set according to actual needs.

• Quiet in compulsion

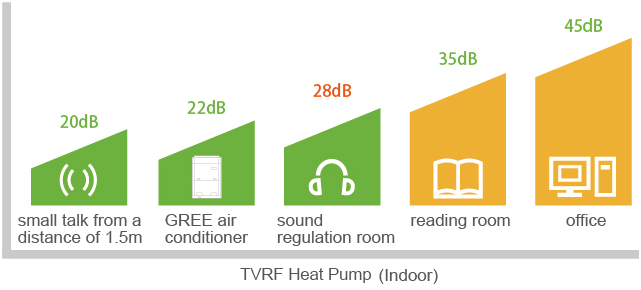

The system can also be set in this mode to ensure low noise as long as it is operating. Noise is as low as 45dB(A).

• Quiet Control

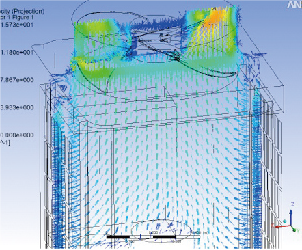

1. Optimized Bossing Design After many times of CFD tests, a new fan bossing structure has been developed to reduce vibration of fan during running. Noise can be reduced by 3-5dB(A).

2. Aerodynamics 3D Axial Fan Compared with conventional fan, it can increase air volume by 12%, improving efficiency as well as lowering noise.

• Quiet Indoor Unit

The indoor unit of the TVRF Heat Pump system also adopts DC inverter motors to realize stepless regulation. According to indoor temperature or people’s actual needs, users can set this mode through wired controller. Noise is as low as 22dB(A).

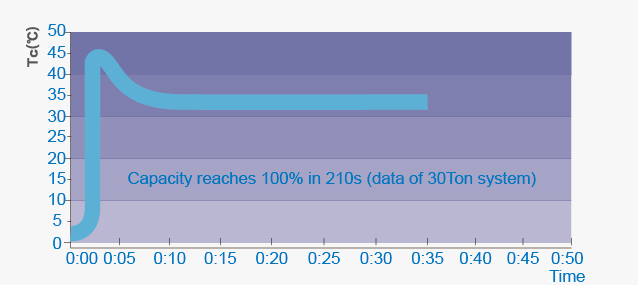

• Fast Start-up in Heating

DC Compressor is first started to avoid too much electric current. Inverter compressor can operate in high frequency once starts up, so as to produce more heat.

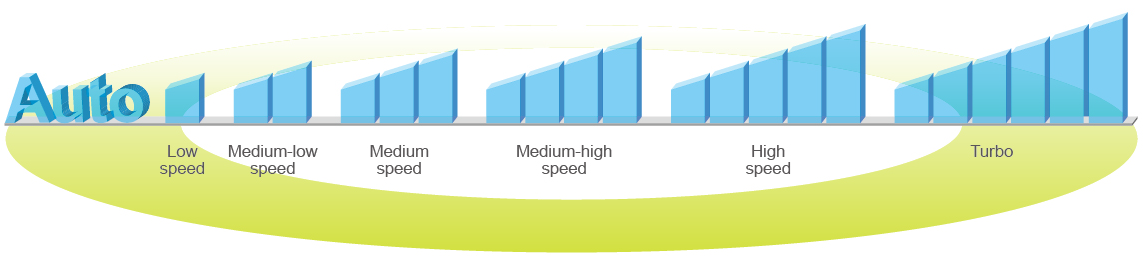

• 7 Levels of Indoor Fan Speed for Option

Indoor fan speed can be set in 7 levels by wired controller. They are auto, low speed, medium-low speed, medium speed, medium-high speed, high speed and turbo. When the wired controller is on, press “FAN” button to set indoor fan speed circularly as below:

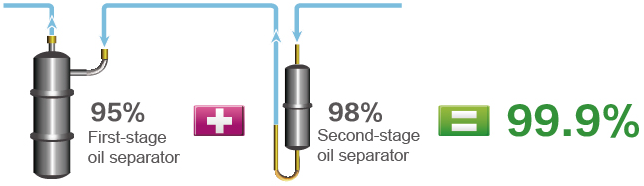

Two-stage Oil Separation Control Technology (Patented)

Through 10 years of research and development, Tosot TVRF Heat Pump has been further upgraded to a high level from electrical components, mechanical parts, control technology to communication technology.

First-stage oil separator adopts a filtration expansion valve with separation efficiency of 98%; Second-stage oil separator will separate the remained 2% refrigerant oil with separation efficiency of 95%. General oil separation efficiency reaches 99.9%.

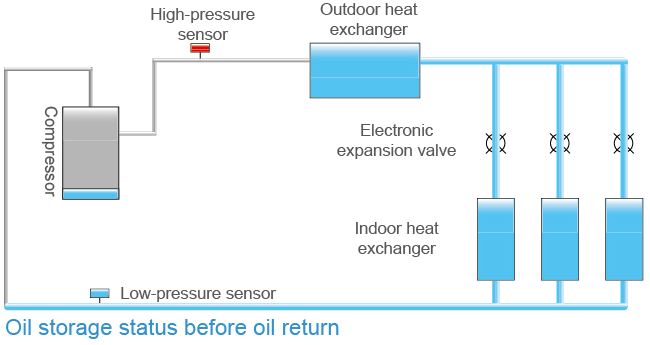

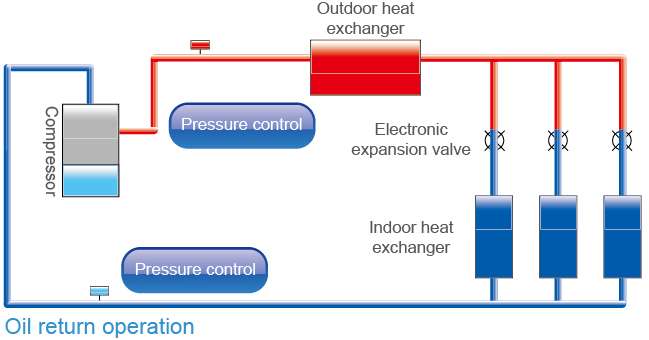

Oil Return Control Technology

• New Oil Return Control

Tosot new oil return control technology effectively controls system oil return and oil storage status of each compressor, which greatly improves the operation lifespan of compressor.

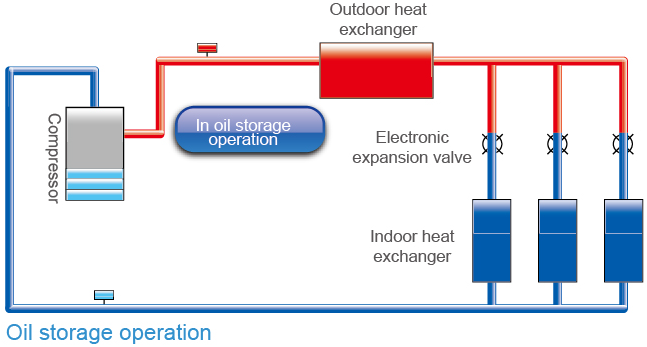

• Specialized Compressor Oil Storage Control

The system applies specialized compressor oil storage technology, which can control the lowest oil level for compressor operation.

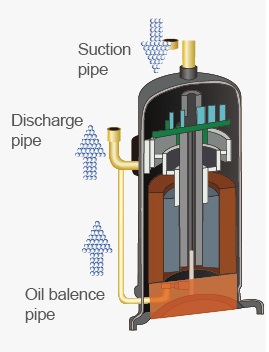

Oil Balance Control Technology

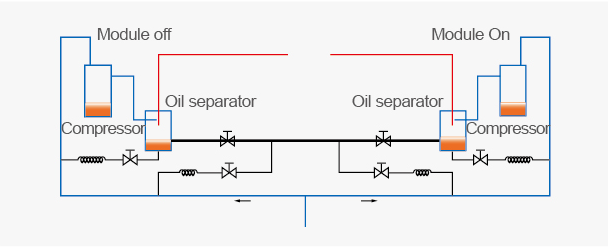

• Oil Balance Between Each Module

Based on the actual status of each module and compressor, the system can regulate compressor’s operation and realize oil balance of each module.

• Oil Balance Between Each Compressor

Refrigerant is taken into the compressor by the suction pipe and then runs through the cooling Discharge system. It can control the pipe oil level and minimum oil volume required by each compressor so as to realize oil balance between each compressor.

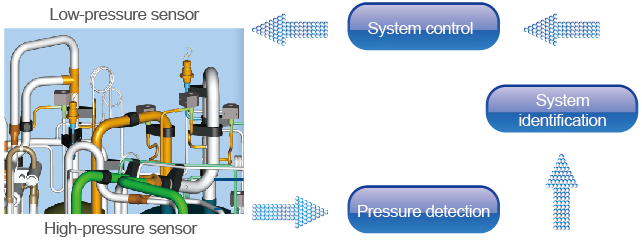

Intelligent Detection Control

• Pressure Sensor Detection Control

Pressure sensor can precisely detect system high pressure and low pressure, and adjust output of fan and compressor, so as to make sure the system can work under the most energy-saving pressure condition.

• Temperature Sensor Detection Control

Various temperature sensors are equipped to detect ambient temperature, indoor temperature and refrigerant’s evaporating temperature, from which the operation status can be measured.

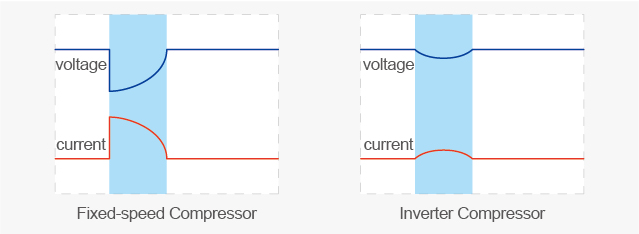

Smaller Impact to Power Grid

The start-up frequency of inverter compressor is gradually increased from OHztothe appointed operation frequency. The start-up current of compressor rotor is decreased by reducing load torque, hence impact to power grid during start-up is reduced and electromagnetic impact to compressor is reduced too.

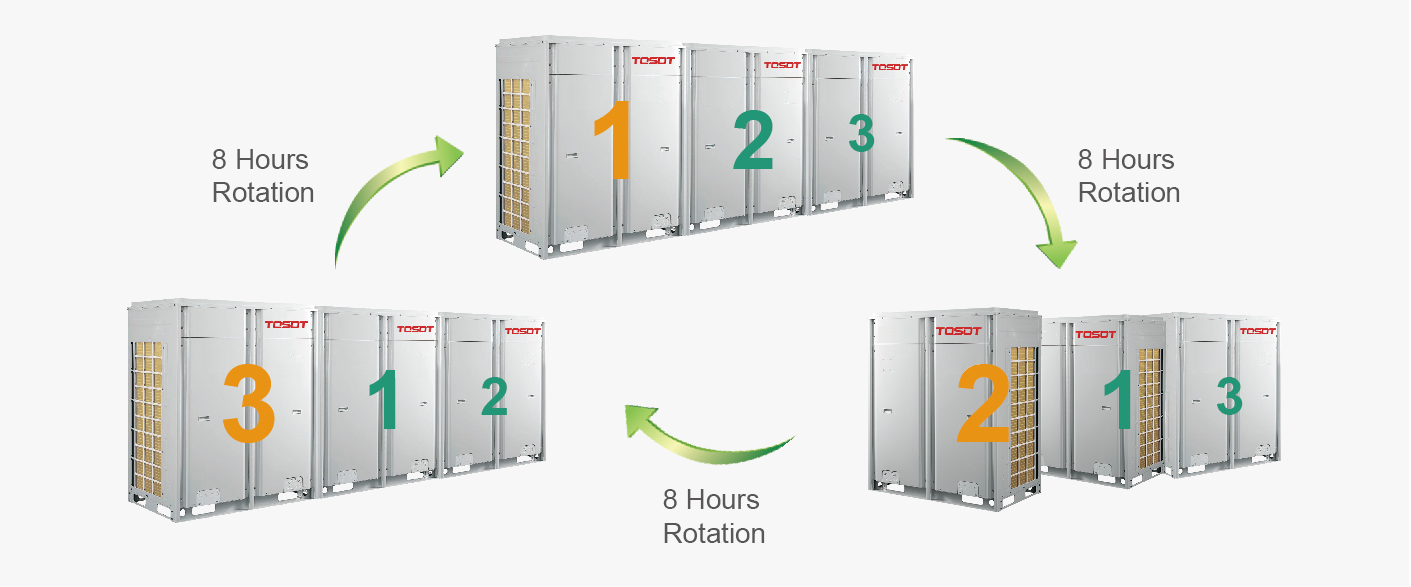

Modules Rotation Operating to Maximize Lifespan

• Modules 8h rotation operating

The operating priority sequence of the outdoor unit modules will be changed without restart when the system accumulatively operates for 8 hours, which can maximize the service life of the system.

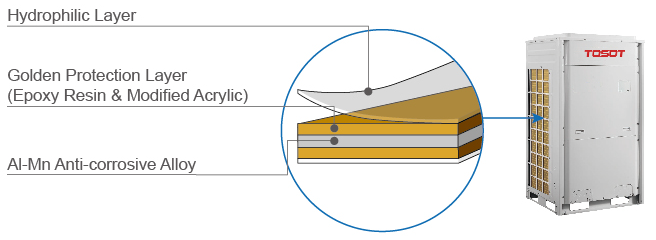

Highly Anticorrosive Golden Fins

The primary material of Golden Fin is Al-Mn(Alu-mium-Manganese) anti-rust alloy, which is coated with the Golden Protection Layer(Components: Epoxy Resin & Modified Acrylic, Silicon free), the anti-corrosive performance in salt-spray testing is 200%-300% higher than normal Blue Fin*.

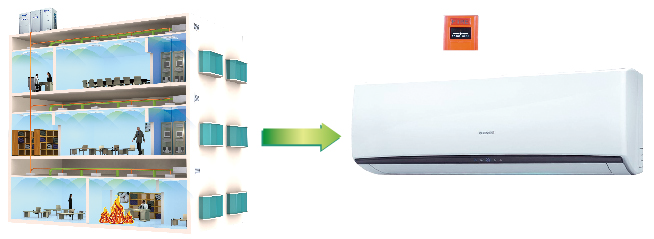

Emergency Auto-Off Control

The outdoor unit can be linked with a fire alarm signal. In case of emergency, unit can automatically turn off to avoid risk or further loss.

Electricity Shortage Identification

The outdoor unit can receive a power signal of electricity shortage. In some places like first-class hotels, if diesel generator is used temporarily for providing electricity, outdoor unit will send the electricity shortage signal to indoor unit. In this case, only VIP rooms can be provided with air conditioning service.

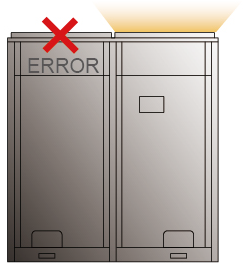

Excellent Emergency Operation Function to Ensure Reliable Operation

• Emergency Function

The TVRF Heat Pump system can realize a combination of 3 outdoor unit modules. When error is occurred to one of the modules, the others will perform the emergency operation to sustain the air conditioning.

All the compressors in each single module are DC Inverter based, when one compressor has error, others will perform the emergency operation.

Double-fan design fan ensures that one fan can still work even if the other one has error.

ODU High Static Pressure Design

System has 4 levels of static pressure that can be set. Up to 0.328 In.W.G pressure can be set for an outdoor unit. This design is especially useful when an indoor unit needs to be placed indoor.

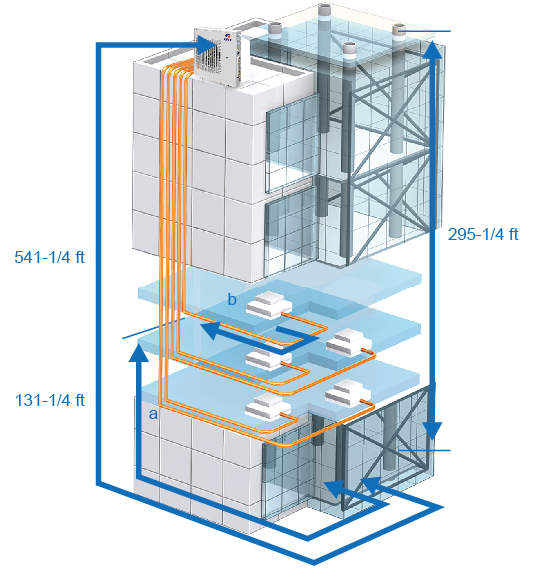

3280-3/4 ft Pipe Design for Flexible Installation

TVRF Heat Pump system can be applied in different types of building construction. One of its advantages is the simple pipe design, which will simplify the installation and reduce installation cost.

• Max total pipe length reaches 3280-3/4 ft (with limitation)

• Actual pipe length between the outdoor unit and the farthest indoor unit:541-1/4 ft

• Max height difference between indoor unit and outdoor unit: 295-1/4 ft

Note:

a: Distance between the first branch and the farthest indoor unit.

b: Distance between the first branch and the nearest indoor unit.

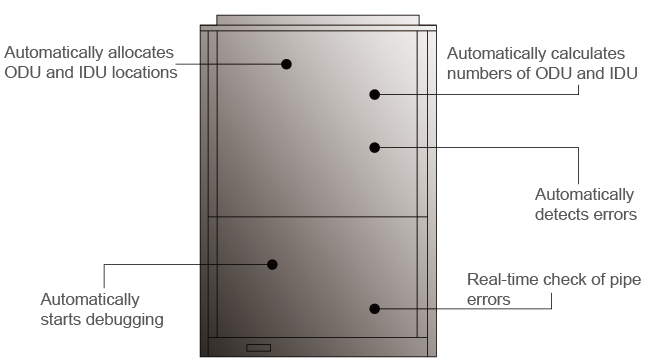

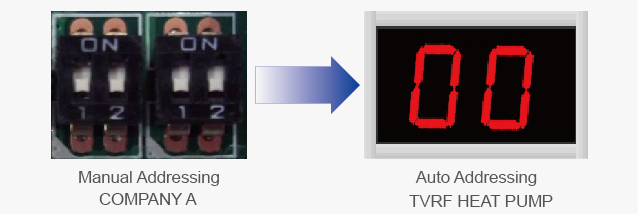

Intelligent Debugging for Convenient Construction

TVRF Heat Pump has five auto debugging features:

• Automatic allocation of IDU and ODU addresses

• Automatic detection of IDU and ODU quantity

• Automatic detection of errors

• Automatic start-up of debugging

• Real-time judgement of pipe errors

Auto Refrigerant Recovery for Convenient Operation

When auto refrigerant recovery function is set and cut-off valve of liquid pipe is closed during maintenance, the system will automatically operate compressor, EXV, solenoid valve and fan, etc. Taking advantage of compressor power, the refrigerant is recovered at the condensing side of outdoor unit to achieve environmental effect. Meanwhile, system low pressure is displayed simultaneously during refrigerant recovery.

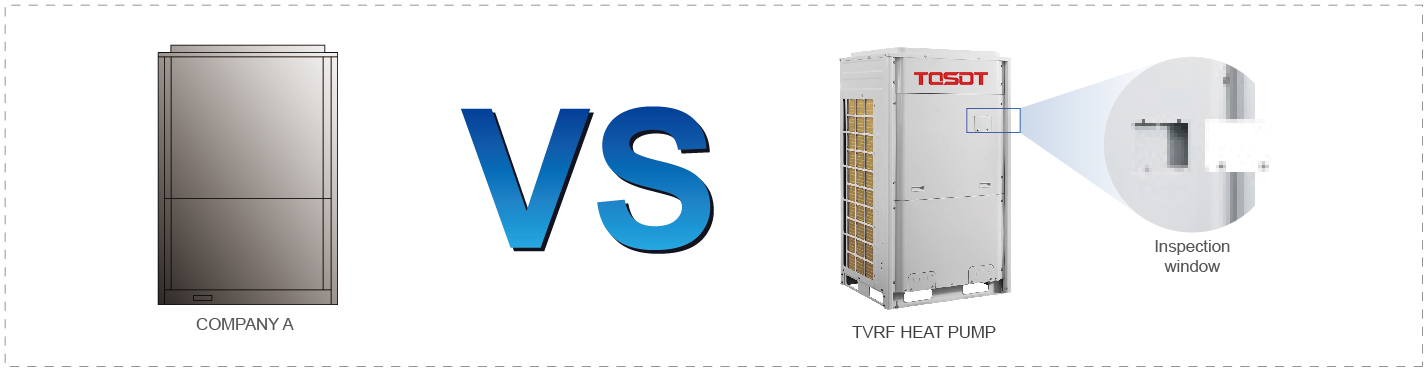

Inspection Window for Convenient Checking

Inspection window is available for quick checking of system operation status. No need to open panel for checking, which will be more time-saving and easier for maintenance.

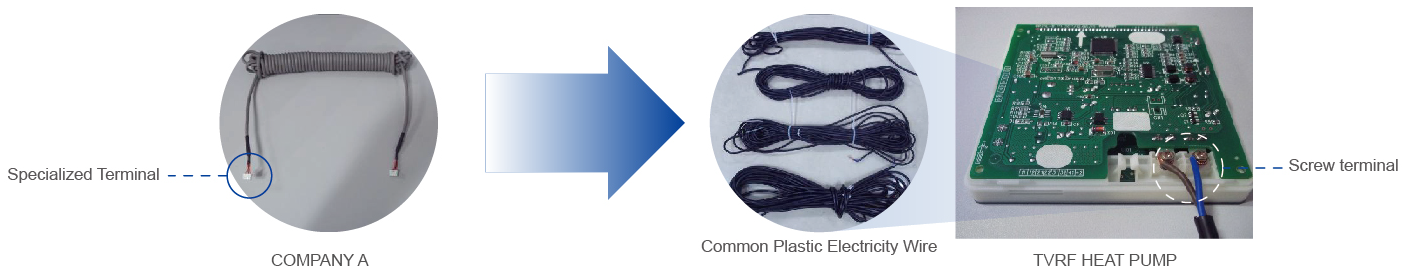

Flexible Wiring

Common wire can meet the communication demand with no need of specialized communication wire. Common sheath twisted pair cable can be used as there is no polarity requirement.

Auto Addressing of Outdoor and Indoor Unit

CAN network is adopted to achieve auto addressing of outdoor and indoor unit. It can allocate IDU and ODU addresses and detect IDU and ODU quantity, which greatly improves construction efficiency.

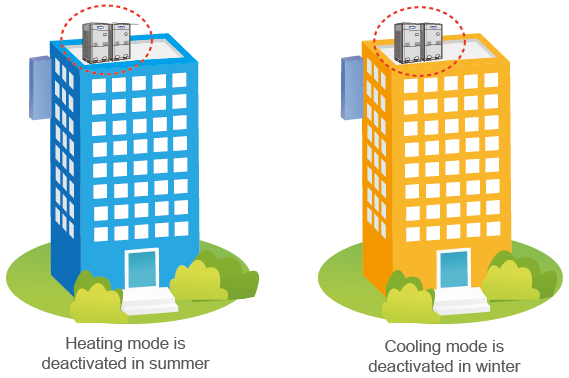

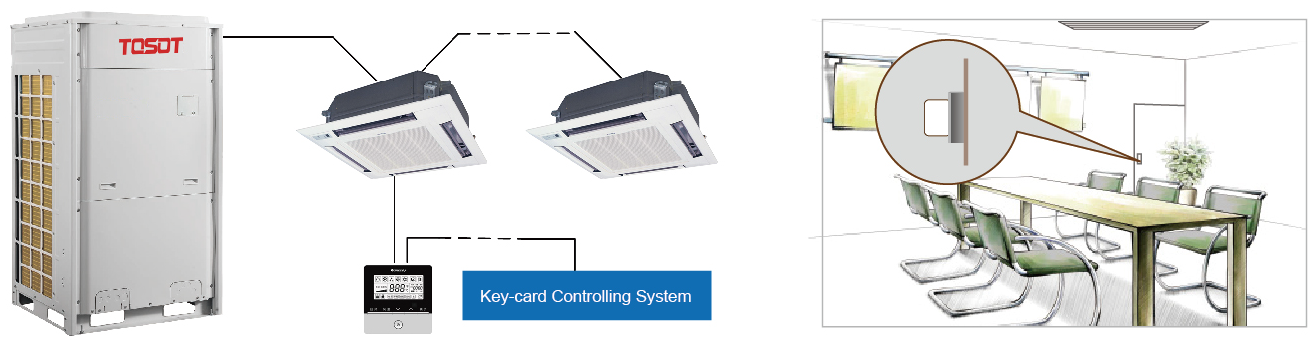

Tosot TVRF Heat Pump provides hotels with unique season setting function and key-card control function.

Season Setting

Cooling or heating mode can be deactivated during a certain season to avoid affecting unit’s normal operation due to mode conflict.

Key-card Control for Hotel Management

The unit can be turned on or off by inserting or removing the key-card. When the key-card is removed, the system can remember all the setting and stop operation. When the key-card is inserted back, the system will be under standby mode or operate according to the status before removing key-card. It is well suited to hotels, restaurants, etc.

Specifications T-VRF Heat Pump

| Models Outdoor Unit | TVRF-OC72KHP/220V | TVRF-OC96KHP/220V | TVRF-OC120KHP/220V | ||

| Capacity | Ton | 6 | 8 | 10 | |

| Capacity | Cooling | Btu/h | 69,000 | 92,000 | 114,000 |

| Heating | Btu/h | 77,000 | 103,000 | 129,000 | |

| Power Supply | V/Ph/Hz | 208/230V~3~60Hz | 208/230V~3~60Hz | 208/230V~3~60Hz | |

| EER – IEER (Ducted/Non-Ducted) | 13.7/13.7 – 21.5/28.1 | 13.2/13.2 – 20/20.26 | 12.4/12.4 – 23.3/25.2 | ||

| High COP 47°F (Ducted/Non-Ducted) | 4.22 / 4.22 | 4.15 / 4.15 | 3.95 / 3.95 | ||

| MOCP | A | 45 | 70 | 100 | |

| Rated Current | A | 30 | 45 | 74 | |

| Maximum drive IDU NO. | unit | 13 | 16 | 19 | |

| Refrigerant Charge Volume | Oz | 229.3 | 398.7 | 416.3 | |

| Airflow | CFM | 6,079 | 8,239 | 8,239 | |

| Sound Pressure Level | dB(A) | 60 | 61 | 63 | |

| Piping connection | Liquid | inch | Φ3/8 | Φ3/8 | Φ1/2 |

| Gas | inch | Φ3/4 | Φ7/8 | Φ1-1/8 | |

| Oil balance | inch | Φ3/8 | Φ3/8 | Φ3/8 | |

| Dimensions WxHxD | Outline | inch | 36-5/8 x 63-1/5 x 30-1/8 | 52-3/4 x 63-1/4 x 30-1/8 | 52-3/4 x 63-1/4 x 30-1/8 |

| Net/Gross Weight | Lbs | 496/518 | 662/694 | 794/827 | |

| Loading Quantity | 40’HQ | set | 24 | 16 | 16 |

Specifications of Outdoor Unit Combinations

| Model | Power Supply | Capacity | Dimensions (WxDxH) | Airflow | ESP | |

| Cooling | Heating | |||||

| V/Ph/Hz | Btu/h | Btu/h | In. | CFM | in.W.G | |

| TVRF-OC72 KHP/220V | 208/230V~3~60Hz | 69,000 | 77,000 | 36-3/5*30-1/8*63-1/5 | 6,080 | 0.33 |

| TVRF-OC96 KHP/220V | 208/230V~3~60Hz | 92,000 | 103,000 | 52-3/4*30-1/8*63-1/5 | 8,230 | 0.33 |

| TVRF-OC120 KHP/220V | 208/230V~3~60Hz | 114,000 | 129,000 | 52-3/4*30-1/8*63-1/5 | 8,230 | 0.33 |

| TVRF-OC144 KHP/220V | 208/230V~3~60Hz | 138,000 | 154,000 | (36-3/5*30-1/8*63-1/5) ×2 | 6,080 x 2 | 0.33 |

| TVRF-OC168 KHP/220V | 208/230V~3~60Hz | 161,000 | 180,000 | (36-3/5*30-1/8*63-1/5)+ (52-3/4*30-1/8*63-1/5) | 6,080 + 8,230 | 0.33 |

| TVRF-OC192 KHP/220V | 208/230V~3~60Hz | 184,000 | 206,000 | (52-3/4*30-1/8*63-1/5) x2 | 8,230 x 2 | 0.33 |

| TVRF-OC216 KHP/220V | 208/230V~3~60Hz | 206,000 | 232,000 | (52-3/4*30-1/8*63-1/5) x2 | 8,230 x 2 | 0.33 |

| TVRF-OC240 KHP/220V | 208/230V~3~60Hz | 228,000 | 258,000 | (52-3/4*30-1/8*63-1/5) x2 | 8,230 x 2 | 0.33 |

| TVRF-OC264 KHP/220V | 208/230V~3~60Hz | 253,000 | 283,000 | (36-3/5*30-1/8*63-1/5)+ (52-3/4*30-1/8*63-1/5) x2 | 6,080 + 8,230x 2 | 0.33 |

| TVRF-OC288 KHP/220V | 208/230V~3~60Hz | 276,000 | 309,000 | (52-3/4*30-1/8*63-1/5) x3 | 8,230 x 3 | 0.33 |

| TVRF-OC312 KHP/220V | 208/230V~3~60Hz | 298,000 | 335,000 | (52-3/4*30-1/8*63-1/5) x3 | 8,230 x 3 | 0.33 |

| TVRF-OC336 KHP/220V | 208/230V~3~60Hz | 320,000 | 361,000 | (52-3/4*30-1/8*63-1/5) x3 | 8,230 x 3 | 0.33 |

| TVRF-OC360 KHP/220V | 208/230V~3~60Hz | 342,000 | 387,000 | (52-3/4*30-1/8*63-1/5) x3 | 8,230 x 3 | 0.33 |